#SCADA development

Explore tagged Tumblr posts

Text

SCADA | SCADA Integrator | SCADA Programmer | SCADA Development

Introduction:

In the realm of industrial automation, Supervisory Control and Data Acquisition (SCADA) systems play a pivotal role in orchestrating complex processes and providing real-time insights. Syscom Automation, a distinguished provider of automation solutions, stands at the forefront in delivering transformative SCADA solutions. This overview explores the significance of Syscom Automation's expertise in SCADA, emphasizing their commitment to revolutionizing industrial control and monitoring.

1. SCADA Mastery:

Syscom Automation exhibits mastery in the design, implementation, and optimization of SCADA systems. Their expertise in SCADA technology positions them as leaders in delivering comprehensive solutions that empower industries with efficient control and centralized data visualization.

2. Comprehensive SCADA Offerings:

Syscom Automation offers a comprehensive suite of SCADA solutions, tailored to meet the diverse needs of industries in the United Arab Emirates (UAE). From real-time process monitoring to data analysis and control system visualization, their SCADA offerings cover the entire spectrum of industrial requirements.

3. Advanced SCADA Technologies:

Syscom Automation stays at the forefront of technological advancements, incorporating advanced SCADA technologies into their solutions. This includes the integration of smart functionalities, data analytics, and connectivity features, providing clients with state-of-the-art SCADA systems that align with modern industrial demands.

4. Customization for Industry-Specific Applications:

Recognizing the uniqueness of each industry, Syscom Automation customizes SCADA solutions to address specific challenges and requirements. Whether it's manufacturing, utilities, energy, or infrastructure, their SCADA systems are engineered to provide tailored solutions that enhance operational efficiency.

5. Real-time Monitoring and Control:

Syscom Automation's SCADA solutions enable real-time monitoring and control of industrial processes. The systems offer a centralized platform where operators can visualize, analyze, and control various elements of the industrial environment, fostering informed decision-making and responsive actions.

6. Integration with PLC and DCS Systems:

Syscom Automation ensures seamless integration of SCADA systems with other automation components such as Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS). This integration creates a cohesive control environment, streamlining operations and enhancing the overall efficiency of industrial processes.

7. Scalability and Future-Readiness:

Syscom Automation designs SCADA solutions with scalability in mind, ensuring that the systems can grow alongside the evolving needs of clients. Their forward-looking approach makes certain that SCADA implementations are future-ready, ready to adapt to emerging technologies and industry trends.

8. Expert Training and Ongoing Support:

Syscom Automation goes beyond system deployment by offering expert training and ongoing support. This ensures that clients and their teams are proficient in utilizing and maintaining the SCADA systems, fostering self-sufficiency and ensuring long-term success.

Conclusion:

Syscom Automation's expertise in SCADA solutions epitomizes a commitment to innovation and efficiency in industrial control. As the UAE continues its industrial evolution, Syscom Automation remains a reliable partner, providing transformative SCADA solutions that empower industries to achieve new heights of control, visibility, and operational excellence.

0 notes

Text

SCADA Development Software: The Backbone of Industrial Automation

If you’re in the industrial automation space, you already know how crucial SCADA (Supervisory Control and Data Acquisition) systems are. They’re the unsung heroes behind manufacturing plants, power grids, water treatment facilities—you name it. But here’s the thing: a SCADA system is only as good as the software powering it. That’s why choosing the right SCADA development software provider is a game-changer.

Why SCADA Development Software Matters

Think of SCADA software as the brain of an industrial operation. It collects real-time data, monitors equipment, and even triggers alerts when something goes wrong. Whether it’s tracking temperature levels in a food processing plant or managing an entire oil refinery, SCADA software gives operators the power to make informed decisions quickly.

But not all SCADA solutions are created equal. A clunky, outdated system can slow down operations and cause unnecessary headaches. That’s why modern SCADA development software focuses on intuitive interfaces, cloud integration, and advanced analytics.

What to Look for in a SCADA Development Software Provider

So, how do you find the right provider? Here are a few things to consider:

Customization – No two industries have the same needs. A good provider will offer flexibility to tailor solutions to your specific requirements.

Scalability – Your business will grow (hopefully!), and your SCADA system should be able to grow with it.

Security – Cybersecurity threats are real. A strong SCADA provider prioritizes data protection.

At the end of the day, investing in a high-quality SCADA development software provider means smoother operations, better efficiency, and fewer surprises. And in the industrial world, that’s worth its weight in gold.

0 notes

Text

Industrial Alarm Management Application

#industrial reporting solution#industrial reporting software#industrial reports development company#reporting tool for industrial automation#reporting software for industrial automation#Scada reporting software#report generation in Scada#best reporting software#Scada report generation#best reporting tools#industrial automation reporting tool#reporting tool for Scada#web based reporting tools#web based reporting software#automated reporting and data analysis software#Batch Reporting Application#Data Log Reporting Application#MKT Analysis#MKT Analysis reports development#Market Analysis application#Alarm Reporting Application

0 notes

Text

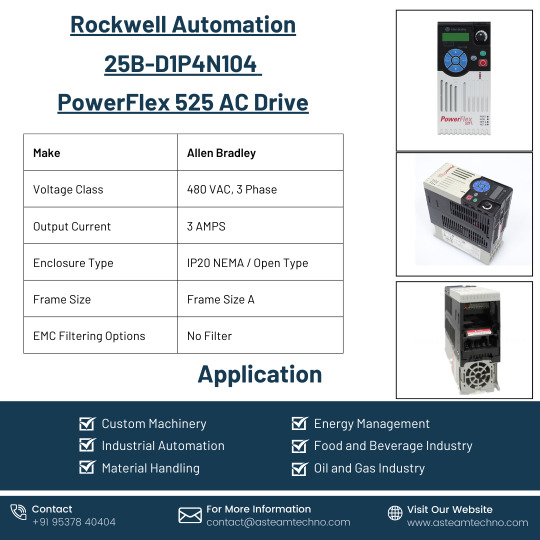

Rockwell Automation 25B-D1P4N104

The Rockwell Automation 25B-D1P4N104 is a part number for a specific variable frequency drive (VFD) within the Allen-Bradley PowerFlex 525 series. The PowerFlex 525 is a compact, versatile, and cost-effective drive designed to control motors in a wide range of industrial applications.

#automation#trending#tumblr trends#viralpost#viral#bestdeals#trendingnow#allen bradley#rockwell automation#plc#SCADA#HMI#powerflex525#application#technical#development#engineering#programs

1 note

·

View note

Text

Investment Secured for Electricity Distribution System Improvement

Announcement of concessional loans and grant amounts by the Asian Development Bank, the European Union, and the Norwegian government, with a total of NPR 72.93 billion secured. Kathmandu — An investment of NPR 72.93 billion (USD 537 million) has been secured to expand, improve, and modernize the transmission and distribution system to make electricity supply within the country reliable and…

#(SASEC)#Arnaud Cauchois#Asian Development Bank#cross-border electricity trade capacity#distribution system#electricity transmission#Kulman Ghising#national transmission#Norwegian government#SCADA

0 notes

Text

The Benefits of Using Modular Switchgear Systems

Why Modern Industries Are Choosing Modular Solutions for Electrical Infrastructure

In today’s fast-paced industrial and commercial environments, electrical safety, efficiency, and scalability are more important than ever. That’s where modular switchgear systems come into play. Designed to meet the evolving needs of various sectors — such as manufacturing, commercial buildings, power utilities, and data centers — modular switchgear offers flexibility, safety, and long-term value.

In this article, we’ll explore the key benefits of using modular switchgear systems, and why they are becoming the preferred choice over traditional switchgear configurations.

What Is a Modular Switchgear System?

A modular switchgear system is a type of switchgear that is built from interchangeable modules or sections. Each module contains electrical components such as circuit breakers, busbars, relays, isolators, and fuses. These modules are pre-engineered and can be easily configured, added, or replaced based on the specific requirements of a facility.

Modular switchgear is used for the protection, control, and isolation of electrical equipment. It is typically found in low voltage (LV) and medium voltage (MV) power distribution systems.

Top Benefits of Modular Switchgear Systems

1. Flexibility and Scalability

One of the most significant advantages of modular switchgear is its flexible design. Whether you’re expanding an existing facility or starting from scratch, modular systems allow you to add or remove units without interrupting the entire system.

· Ideal for facilities expecting future expansion

· Easy to customize layout based on project demands

· Supports phased development in infrastructure projects

2. Enhanced Safety and Reliability

Modern modular switchgear systems are designed with advanced safety features. Segregated compartments, arc fault containment, and reliable insulation materials ensure operator safety and system reliability.

· Reduces risk of electrical faults and arc flashes

· Complies with IEC and ANSI safety standards

· Minimizes downtime during maintenance or upgrades

3. Ease of Installation and Maintenance

Thanks to its pre-fabricated modules, modular switchgear is faster and easier to install compared to conventional systems. It also simplifies troubleshooting and routine maintenance.

· Less on-site wiring and civil work required

· Individual modules can be isolated for servicing

· Reduces maintenance costs and system downtime

4. Compact and Space-Saving Design

With limited space in modern industrial setups, compactness is crucial. Modular switchgear systems are designed for space optimization, making them perfect for high-density environments.

· Vertical and horizontal expansion possible

· Reduced footprint compared to traditional gear

· Neat and organized layout improves cable management

5. Future-Proof and Upgrade-Friendly

Industries evolve, and so should your electrical infrastructure. Modular switchgear supports easy integration of new technologies, such as remote monitoring, IoT-enabled control systems, and energy management solutions.

· Supports integration with SCADA and BMS systems

· Accommodates evolving energy needs

· Long lifecycle with upgrade options

6. Cost-Effective Over the Long Term

Though the initial investment may be higher than conventional switchgear, the long-term benefits of modular systems — including reduced downtime, lower maintenance costs, and scalability — make them a cost-effective solution.

· Lower total cost of ownership (TCO)

· Reduced operational expenses

· Optimized energy efficiency

Applications of Modular Switchgear Systems

Modular switchgear is suitable for a wide range of applications, including:

🏢 Commercial buildings

🏭 Industrial plants

⚡ Power generation and distribution

🖥 Data centers

🏥 Hospitals

🏗 Infrastructure projects and smart cities

Conclusion

If you’re looking for a smart, scalable, and reliable solution for your electrical distribution system, modular switchgear systems are a worthy investment. With benefits ranging from safety and efficiency to cost savings and future readiness, they offer a significant upgrade over traditional switchgear models.

2 notes

·

View notes

Text

purOS Satınalma Yönetimi

tediye nedir

muhtasar nedir

smma nedir

mutabakat nedir

crm nedir

erp açılımı

iskonto nasıl hesaplanır

kurumsal fatura nedir

irsaliye nedir

iskonto nedir

kreatif ne demek

yapay zeka seslendirme

Kiosk Nedir?

Özel yazılım

yazılım hizmetleri

yazılım geliştirme

mrp yazılımı

mrp modülü

mrp sistemi

mrp programı

mrp nedir

mrp açılımı

malzeme ihtiyaç planlama

satın alma yazılımı

satın alma programı

teklif yönetimi yazılımı

tedarikçi sipariş yönetimi

satın alma programları

satın alma yönetim programı

satın alma sistemi

satın alma sistemi programı

siparişli satın alma sistemi

satın alma modülü

merkezi satın alma sistemi

tedarik yönetim sistemi

satın alma ve talep yönetimi

satın alma ve tedarikçi yazılımı

tedarik zinciri yönetim programı

kurumsal satın alma sistemi

kurumsal satın alma programı

satın alma bilgi sistemi

satın alma yönetim programı

muhasebe yazılımları

müşteri ilişkileri yönetimi

enflasyon muhasebesi nedir

kdv hesaplama

adsense nedir

tevkifat nedir

p2p nedir

satın alma süreci

yazılım programları

scada nedir

scada yazılımı nedir

github nedir

işletmelerde verimlilik nedir

ik portalı nedir

erp nedir

erp sistemi nedir

erp programı nedir

satınalma yazılımı

purOS blog

purOS hizmetleri

malzeme yönetimi

teslimat yönetimi

sipariş yönetimi

teklif yönetimi

talep yönetimi

satınalma sistemi faydaları

purOS ne fayda saglar

purOS sektörler

neden purOS

satın alırken kazanın

yazılımı keşfedin

satınalma yönetimi

purOS hakkında

purOS

yazılım

instagram mavi tık nasıl alınır

yüzde hesaplama

developer nedir

google translate kullanımı

kümülatif vergi matrahı google trends nedir

5 notes

·

View notes

Text

System Integrator Market Size, Share, Trends, Demand, Industry Growth and Competitive Outlook

Global System Integrator Market - Size, Share, Demand, Industry Trends and Opportunities

Global System Integrator Market, By Service (Infrastructure Integration, Application Integration, Consulting), Technology (Supervisory Control and Data Acquisition (SCADA), Programmable Logic Controller (PLC), Programmable Automation Controller (PAC), Remote Terminal Unit (RTU), Distributed Control System (DCS), Manufacturing Execution System (MES) and Manufacturing Operations Management (MOM), Product Lifecycle Management (PLM), Human-Machine Interface (HMI), Advanced Process Control (APC), Operator Training Simulator (OTS), Safety Automation), End User (IT and Telecom, BFSI, Healthcare, Retail, Manufacturing, Energy and Utility) - Industry Trends.

Access Full 350 Pages PDF Report @

**Segments**

- **By Service:** The system integrator market can be segmented based on the services offered, such as consulting, design and development, maintenance and support, and integration & implementation services. Organizations often require system integrators to provide expertise in these areas to ensure the successful integration of technologies into their existing infrastructure.

- **By End-User:** Another key segmentation factor for the system integrator market is based on the end-user industries served. Various industries like IT & telecom, BFSI, healthcare, manufacturing, retail, and others have distinct technology requirements, which necessitate the need for specialized system integrators catering to their specific needs.

- **By Region:** Geographical segmentation plays a crucial role in the system integrator market as technology adoption and requirements vary across regions. Different regions like North America, Europe, Asia Pacific, Latin America, and Middle East & Africa have unique market dynamics that influence the demand for system integration services.

**Market Players**

- **Accenture:** One of the prominent players in the system integrator market, Accenture offers a wide range of consulting, technology, and outsourcing services to help organizations integrate and optimize their IT infrastructure.

- **IBM:** IBM is another key market player providing system integration services to address the complex technology needs of businesses across various industries.

- **Deloitte:** Deloitte's system integration services focus on helping organizations streamline their operations and enhance efficiency through the seamless integration of technologies.

- **Capgemini:** Capgemini is a global leader in consulting, technology services, and digital transformation, providing advanced system integration solutions to enable businesses to achieve their strategic objectives.

- **TCS (Tata Consultancy Services):** TCS is a leading IT services, consulting, and business solutions organization that offers comprehensive system integration services to drive innovation and maximize operational performance for its clients.

The system integrator market is witnessing significant growth due to the increasing digitization of businesses across industries. As organizations strive to enhance their operational efficiency and leverage advancedThe system integrator market is experiencing robust growth as businesses across industries continue to digitize their operations to improve efficiency and stay competitive in the modern business landscape. With the increasing complexity of technology ecosystems and the need for seamless integration of various platforms and solutions, the demand for system integrators is on the rise. These market players play a crucial role in helping organizations navigate the challenges associated with integrating new technologies into their existing infrastructure.

Segmentation of the system integrator market based on services offered provides insights into the diverse needs of organizations seeking integration solutions. Consulting services are essential for understanding the specific requirements and goals of the business, while design and development services focus on creating tailored solutions to meet these objectives. Maintenance and support services are crucial for ensuring the smooth functioning of integrated systems, while integration and implementation services play a key role in executing the integration process effectively. By catering to these different service requirements, system integrators can address the unique needs of their clients and deliver value-added solutions.

The segmentation of the system integrator market by end-user industries reflects the diverse technology requirements across different sectors. Industries such as IT & telecom, BFSI, healthcare, manufacturing, and retail have specific technological needs that require specialized expertise for successful integration. System integrators with industry-specific knowledge and experience can provide tailored solutions that address the unique challenges faced by organizations in these sectors. By understanding the distinct requirements of various industries, system integrators can develop customized integration strategies that drive business growth and innovation.

Geographical segmentation also plays a significant role in the system integrator market, as technology adoption and market dynamics vary across regions. North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa each present unique opportunities and challenges for system integrators. Local regulations, infrastructure, and business practices all influence the demand for integration services in these regions. By understanding the specific needs of each market, system integrators can tailor their services to meet the requirements of local businesses and drive growth in the respective regions.

Prominent market players such**Segments**

- **By Service:** The system integrator market is segmented based on the services offered, including consulting, design and development, maintenance and support, and integration & implementation services. Organizations rely on system integrators to provide expertise in these areas to ensure successful technology integration.

- **By End-User:** The system integrator market is segmented based on the end-user industries served, such as IT & telecom, BFSI, healthcare, manufacturing, and retail. Different industries have specific technology requirements, leading to the need for specialized system integrators catering to their unique needs.

- **By Region:** Geographical segmentation is crucial in the system integrator market as technology adoption varies across regions. North America, Europe, Asia Pacific, Latin America, and Middle East & Africa each have distinct market dynamics influencing the demand for system integration services.

**Market Players**

- **Accenture:** Offering consulting, technology, and outsourcing services, Accenture aids organizations in integrating and optimizing their IT infrastructure.

- **IBM:** IBM provides system integration services to address complex technology needs across various industries.

- **Deloitte:** Deloitte focuses on helping organizations streamline operations and enhance efficiency through seamless technology integration.

- **Capgemini:** As a global leader in consulting and digital transformation, Capgemini delivers advanced system integration solutions for businesses to achieve strategic objectives.

- **TCS (Tata Consultancy Services):** TCS, a leading IT services organization, offers comprehensive system integration services to drive innovation and

Core Objective of System Integrator Market:

Every firm in the System Integrator Market has objectives but this market research report focus on the crucial objectives, so you can analysis about competition, future market, new products, and informative data that can raise your sales volume exponentially.

Size of the System Integrator Market and growth rate factors.

Important changes in the future System Integrator Market.

Top worldwide competitors of the Market.

Scope and product outlook of System Integrator Market.

Developing regions with potential growth in the future.

Tough Challenges and risk faced in Market.

Global System Integrator top manufacturers profile and sales statistics.

Key takeaways from the System Integrator Market report:

Detailed considerate of System Integrator Market-particular drivers, Trends, constraints, Restraints, Opportunities and major micro markets.

Comprehensive valuation of all prospects and threat in the

In depth study of industry strategies for growth of the System Integrator Market-leading players.

System Integrator Market latest innovations and major procedures.

Favorable dip inside Vigorous high-tech and market latest trends remarkable the Market.

Conclusive study about the growth conspiracy of System Integrator Market for forthcoming years.

Frequently Asked Questions

What is the Future Market Value for System Integrator Market?

What is the Growth Rate of the System Integrator Market?

What are the Major Companies Operating in the System Integrator Market?

Which Countries Data is covered in the System Integrator Market?

What are the Main Data Pointers Covered in System Integrator Market Report?

Browse Trending Reports:

Video Conferencing Systems Market Wireless Gigabit Market Functional Mushroom Powder Market Water Based Lamination Adhesive Market Wash Basins Market X-ray Digital Imaging Systems Market Water Tight Doors Market Data Center Rack Power Distribution Unit (PDU) Market Point-of-Care Testing (POCT) Market Melamine Formaldehyde Market Naphthalene Derivatives Market Shape Memory Alloy Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]

0 notes

Text

How Wireless Control Systems Make Buildings Smarter In Singapore?

Convenience and efficiency have transitioned from mere luxuries to must-haves in an era of smart living. The gradual transition of homes, offices, and commercial spaces in Singapore to the domain of automation has led to an steadily growing demand for highly reliable control systems that can function in the present and the future. Among these control solutions, Wireless Control Systems and KNX control system Singapore stand as very popular contenders offering great promise to the local market.

The Rise of Wireless Control Systems in Singapore

Wireless control system Singapore are gaining popularity in Singapore owing to their flexibility and ease of installation. These systems are well suited for retrofit applications in older buildings or upgrading in existing architecture as they require minimal wiring. Because of their wireless nature, control for lighting, climate, and security can offer seamless integration and remote access via mobile phones or tablets.

With space at a premium in tightly held urban homes, a wireless control system Singapore allows managing several devices without the clutter of switches and visible cabling. Property developers and interior designers alike are recommending wireless systems not only for their minimalist look but also for their ability to scale into the future. From HDB flats to private condos, wireless technology allows developers to create a more responsive intelligent living space.

KNX Control Systems-

The Gold Standard in Smart Integration. While wireless installations have captured the market with their flexibility, KNX control of Singapore boasts a strong, standardized, and highly wired KNX infrastructure. As a worldwide recognized protocol, KNX is able to cover the needs of a large number of devices and manufacturers, making it most suitable for investment and complex automation projects long-term.

Control control lighting, hvac, blinds, and energy consumption from the same interface, and after installing a KNX system, you'll find that devices communicate perfectly, thus improving energy effectiveness and better environmental control.

Making a Choice Depending on Systems Needed

From the viewpoint of SCADA, when deciding between wireless control system Singapore versus KNX control system Singapore, the most crucial factor being considered is the project scale, cost, and long-term goals. Moreover, for short setups and smaller areas, wireless systems make a lot of economic sense and are very friendly to the user. KNX stands undefeated in reliability and customization for larger developments or integrated building management systems.

Conclusion

The market for smart homes and building automation within Singapore can be said to be changing very fast. Whether you are looking for a wireless control system Singapore that is easy to change or for a highly integrated KNX control system Singapore, investing in smart technology will boost comfort in addition to adding some value to the property in the long run. If one partners with experienced providers and chooses an appropriate model for the situation, a space can evolve beautifully into an intelligent environment.

#wireless control system singapore#KNX control system singapore#heavy duty led lights#buy led panel online#led track light#dotless led strip light

0 notes

Text

SCADA development | SCADA development in Dubai, UAE

Introduction

Supervisory Control and Data Acquisition (SCADA) systems are at the heart of industrial automation, enabling efficient monitoring and control of industrial processes. we will explore the process of SCADA development and the key steps involved in building robust and reliable automation systems.

Understanding SCADA Development

SCADA development involves the design, implementation, and integration of software and hardware components to create a fully functional SCADA system. The goal is to develop a system that can collect, process, and display real-time data from industrial processes, allowing operators to monitor and control them effectively.

Key Steps in SCADA Development

Requirements Gathering: The first step in SCADA development is understanding the specific requirements of the client or organization. This involves identifying the processes to be monitored and controlled, the desired functionality of the system, and any regulatory or compliance requirements.

System Design: Based on the requirements, the next step is to design the architecture of the SCADA system. This includes determining the hardware components, such as sensors and actuators, and the software applications, such as HMI (Human-Machine Interface) and database systems, that will be used.

Database Design: SCADA systems generate a large amount of data, so designing an efficient and scalable database structure is crucial. The database should be able to handle real-time data acquisition and provide quick access to historical data for analysis.

Software Development: SCADA software development involves creating the necessary applications for data acquisition, real-time monitoring, alarming, and control. This can include developing communication protocols, graphical user interfaces, and integrating with hardware devices.

Integration with Hardware: SCADA systems interface with various hardware devices, such as PLCs (Programmable Logic Controllers) and RTUs (Remote Terminal Units), to collect data and control industrial processes. The development team ensures seamless integration between the software and hardware components.

Testing and Validation: Rigorous testing is essential to ensure the system functions as intended. This includes verifying data accuracy, testing alarms and alerts, and validating control functions. The system is tested under different scenarios and conditions to ensure reliability and responsiveness.

Installation and Commissioning: After successful testing, the SCADA system is installed and commissioned in the operational environment. This involves setting up the hardware, configuring the software, and establishing network connections.

Training and Support: End-user training is an important aspect of SCADA development. Operators need to be familiar with the system, understand how to access and analyze data, and effectively utilize the control functions. Ongoing technical support is also provided to address any issues or concerns that may arise.

Benefits of SCADA Development

Improved Efficiency: SCADA systems automate manual tasks, reducing human errors and increasing operational efficiency.

Real-time Monitoring: SCADA provides real-time data visualization, empowering operators to make informed decisions quickly.

Increased Productivity: With SCADA systems, processes can be optimized for maximum productivity, reducing downtime and boosting output.

Enhanced Safety: SCADA systems monitor and alert operators to potential hazards or abnormal conditions, improving overall safety in industrial environments.

Data Analysis for Optimization: SCADA systems store historical data, which can be analyzed for process optimization, predictive maintenance, and troubleshooting.

Conclusion

SCADA development is a complex and iterative process that requires a deep understanding of industrial processes, software development, and hardware integration. With careful planning, design, and implementation, a robust and reliable SCADA system can be built. The benefits of SCADA development include increased efficiency, improved productivity, enhanced safety, and the ability to harness valuable data for optimization.

If you are considering SCADA development for your organization, we have a team of experts ready to assist you. Contact us today to explore how SCADA can transform your industrial automation processes.

0 notes

Text

The Role of an Automation Engineer in Modern Industry

In today’s fast-paced technological landscape, automation has become the cornerstone of efficiency and innovation across industries. At the heart of this transformation is the automation engineer—a professional responsible for designing, developing, testing, and implementing systems that automate processes and reduce the need for human intervention.

Who Is an Automation Engineer?

An automation engineer specializes in creating and managing technology that performs tasks with minimal human oversight. They work across a variety of industries including manufacturing, software development, automotive, energy, and more. Their primary goal is to optimize processes, improve efficiency, enhance quality, and reduce operational costs.

Key Responsibilities

Automation engineers wear many hats depending on their domain. However, common responsibilities include:

Designing Automation Systems: Creating blueprints and system architectures for automated machinery or software workflows.

Programming and Scripting: Writing code for automation tools using languages such as Python, Java, C#, or scripting languages like Bash or PowerShell.

Testing and Debugging: Developing test plans, running automated test scripts, and resolving bugs to ensure systems run smoothly.

Maintenance and Monitoring: Continuously monitoring systems to identify issues and perform updates or preventive maintenance.

Integration and Deployment: Implementing automated systems into existing infrastructure while ensuring compatibility and scalability.

Collaboration: Working closely with cross-functional teams such as developers, quality assurance, operations, and management.

Types of Automation Engineers

There are several specializations within automation engineering, each tailored to different industries and objectives:

Industrial Automation Engineers – Focus on automating physical processes in manufacturing using tools like PLCs (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition), and robotics.

Software Automation Engineers – Automate software development processes including continuous integration, deployment (CI/CD), and testing.

Test Automation Engineers – Specialize in creating automated test scripts and frameworks to verify software functionality and performance.

DevOps Automation Engineers – Streamline infrastructure management, deployment, and scaling through tools like Jenkins, Ansible, Kubernetes, and Docker.

Skills and Qualifications

To thrive in this role, an automation engineer typically needs:

Technical Skills: Proficiency in programming languages, scripting, and automation tools.

Analytical Thinking: Ability to analyze complex systems and identify areas for improvement.

Knowledge of Control Systems: Especially important in industrial automation.

Understanding of Software Development Life Cycle (SDLC): Crucial for software automation roles.

Communication Skills: To effectively collaborate with other teams and document systems.

A bachelor's degree in engineering, computer science, or a related field is usually required. Certifications in tools like Siemens, Rockwell Automation, Selenium, or Jenkins can enhance job prospects.

The Future of Automation Engineering

The demand for automation engineers is expected to grow significantly as businesses continue to embrace digital transformation and Industry 4.0 principles. Emerging trends such as artificial intelligence, machine learning, and Internet of Things (IoT) are expanding the scope and impact of automation.

Automation engineers are not just contributors to innovation—they are drivers of it. As technology evolves, their role will become increasingly central to building smarter, safer, and more efficient systems across the globe.

Conclusion

An automation engineer is a vital link between traditional processes and the future of work. Whether improving assembly lines in factories or ensuring flawless software deployment in tech companies, automation engineers are transforming industries, one automated task at a time. Their ability to blend engineering expertise with problem-solving makes them indispensable in today’s digital world.

0 notes

Text

Top 5 Factors to Consider When Choosing Switchgear in Qatar

The energy infrastructure in Qatar is evolving rapidly, driven by ambitious development plans, a booming construction sector, and growing demand for reliable and efficient power distribution systems. As such, selecting the right switchgear — an essential component in electrical distribution networks — is more important than ever. Whether for industrial, commercial, or residential projects, choosing the appropriate switchgear can significantly impact safety, operational reliability, and long-term costs.

In this article, we explore the top five factors to consider when choosing switchgear in Qatar, keeping in mind the country’s unique climatic, industrial, and regulatory environment.

1. Environmental and Climatic Conditions

Why It Matters:

Qatar’s climate is characterized by extreme heat, high humidity, and frequent dust storms, which can adversely affect the performance and longevity of electrical equipment.

What to Consider:

· Ingress Protection (IP) Ratings: Choose switchgear with high IP ratings (e.g., IP65 or above) to ensure resistance to dust and moisture.

· Temperature Tolerance: Equipment should be capable of operating in ambient temperatures above 45°C without derating.

· Corrosion Resistance: Opt for enclosures made from stainless steel or coated with anti-corrosive materials to withstand coastal and desert environments.

Tip:

Ask for switchgear that has been tested and certified for desert and tropical climates to ensure long-term reliability.

2. Compliance with Local Regulations and Standards

Why It Matters:

Qatar’s construction and energy sectors are tightly regulated. Non-compliance with local codes can lead to project delays, penalties, or unsafe installations.

What to Consider:

· Kahramaa Regulations: Ensure the switchgear complies with Qatar General Electricity & Water Corporation (Kahramaa) specifications.

· International Standards: Equipment should meet IEC (International Electrotechnical Commission) or ANSI standards for design and performance.

· Vendor Certifications: Choose manufacturers and suppliers who are approved by local authorities and have a track record of regulatory compliance.

Tip:

Request documentation and third-party certification to verify compliance before purchase.

3. System Voltage and Current Ratings

Why It Matters:

Mismatched ratings can lead to equipment failure, increased downtime, or even safety hazards.

What to Consider:

· Voltage Level: Identify whether your application requires low-voltage (LV), medium-voltage (MV), or high-voltage (HV) switchgear.

· Short-Circuit Withstand Capacity: The switchgear must handle the maximum fault current expected in the system.

· Load Type and Growth: Consider both current and future load expansions when sizing the switchgear.

Tip:

Conduct a detailed load analysis with a qualified electrical engineer to ensure proper equipment sizing.

4. Reliability and Safety Features

Why It Matters:

Switchgear is central to ensuring electrical safety and minimizing power outages, especially in critical infrastructure.

What to Consider:

· Arc Flash Protection: Look for internal arc classification (IAC) and arc-resistant features.

· Automation and Remote Monitoring: Smart switchgear with SCADA integration can improve uptime and facilitate preventive maintenance.

· Redundancy and Segmentation: Ensure the switchgear design allows for maintenance without shutting down the entire system.

Tip:

Consider intelligent switchgear with diagnostic features to enable predictive maintenance and minimize human error.

5. Availability of Local Support and Spare Parts

Why It Matters:

Even the best switchgear can require maintenance or part replacement. Having quick access to support minimizes downtime and operational losses.

What to Consider:

· Local Service Network: Choose brands with authorized service centers or partners in Qatar.

· Spare Parts Availability: Ensure that spare parts can be sourced locally with minimal lead time.

· Training and Technical Support: Ask about operator training, maintenance contracts, and emergency response services.

Tip:

Opt for suppliers with a strong presence in the GCC region and a proven track record in Qatar’s market.

Conclusion

Choosing the right switchgear in Qatar requires a thoughtful evaluation of environmental, regulatory, technical, and logistical factors. With the right equipment, businesses and developers can ensure electrical safety, regulatory compliance, and long-term operational efficiency in one of the world’s most challenging climates.

When evaluating options, always consider:

· Local conditions and regulatory landscape

· Equipment ratings and design

· Vendor support and technical reliability

By focusing on these core considerations, stakeholders can make informed, cost-effective, and future-ready decisions for their electrical infrastructure projects in Qatar.

#electrical equipment#qatar#switchgear#electrical#911 abc#arcane#artists on tumblr#batman#cats of tumblr#cookie run kingdom

1 note

·

View note

Text

Future of Operational Technology Market: Trends and Predictions

According to a recent report published by Grand View Research, Inc., the global operational technology (OT) market is expected to reach a valuation of USD 364.74 billion by 2030. The market is projected to grow at a compound annual growth rate (CAGR) of 9.6% from 2025 to 2030. This anticipated growth is primarily fueled by the rising demand for robust OT security solutions, which has become increasingly critical due to the growing reliance on digital technologies within industrial environments. As industrial systems become more digitized and interconnected, they become more susceptible to cybersecurity threats, thus heightening the need for fortified protection mechanisms.

One of the key driving forces behind this market trend is the implementation of stringent government regulations focused on cybersecurity. These regulations—such as comprehensive cybersecurity frameworks for Industrial Control Systems (ICS)—mandate that organizations adopt enhanced security protocols to protect their infrastructure. Additionally, as Information Technology (IT) and Operational Technology (OT) systems converge, the lines between corporate and industrial networks blur, creating more entry points for cyber threats to infiltrate OT systems through IT channels. This growing interconnectedness significantly elevates the risk profile, leading to an increased need for resilient and secure OT systems to protect vital industrial operations and ensure business continuity.

Operational technologies refer to the hardware and software systems that are used to monitor, control, and manage physical processes and equipment in real-world environments. These technologies include Distributed Control Systems (DCS), Supervisory Control and Data Acquisition (SCADA) systems, Programmable Logic Controllers (PLCs), Building Management Systems (BMS), Computer Numerical Control (CNC) systems, and more. Such systems play a critical role in managing key infrastructure, including manufacturing plants, power generation stations, and water treatment facilities. By ensuring real-time monitoring and control, OT systems are essential for maintaining operational efficiency, safety, and reliability, and for protecting against system failures and environmental hazards.

The operational technology market is highly dynamic and competitive, with companies continuously adapting to evolving challenges and opportunities. Market participants are heavily investing in research and development to produce innovative solutions that enhance system resilience. The integration of artificial intelligence (AI) and machine learning into OT security offerings is a prominent trend, enabling predictive maintenance, real-time threat detection, and automated response mechanisms.

For example, Huawei Technologies Co., Ltd. is playing a pivotal role in the digital transformation of the manufacturing sector. The company is actively promoting the convergence of Information and Communications Technology (ICT) with Operational Technology, aiming to create smart, interconnected production environments. Huawei's initiatives are closely aligned with major global industrial strategies such as Germany’s Industry 4.0, China’s Made in China 2025, and the U.S. Industrial Internet. Through these efforts, the company is contributing to the modernization of manufacturing ecosystems, fostering digitally integrated, intelligent, and automated industrial processes that are more efficient, adaptive, and secure.

Curious about the Operational Technology Market? Download your FREE sample copy now and get a sneak peek into the latest insights and trends.

Frequently Asked Questions (FAQ) – Global Operational Technology Market

1. What is the projected size of the global operational technology market by 2030?

According to a report by Grand View Research, Inc., the global operational technology market is expected to reach USD 364.74 billion by 2030, growing at a compound annual growth rate (CAGR) of 10% from 2024 to 2030.

2. What factors are driving the growth of the OT market?

The growth of the OT market is driven by several key factors:

• Increased reliance on digital technologies: Industries are adopting digital solutions for enhanced efficiency, leading to a higher demand for OT systems.

• Rising cybersecurity concerns: The growing threat of cyberattacks has heightened the need for robust OT security measures.

• Government regulations: Strict cybersecurity frameworks and policies are compelling organizations to implement comprehensive OT security protocols.

• Integration of IT and OT systems: The convergence of IT and OT increases interconnectedness, exposing OT systems to potential cyber threats.

3. What are operational technologies, and where are they used?

Operational technologies encompass hardware and software systems that monitor and control physical processes in various industries. Examples include:

• Distributed Control Systems (DCS)

• Supervisory Control and Data Acquisition (SCADA) systems

• Programmable Logic Controllers (PLCs)

• Building Management Systems (BMS)

• Computer Numerical Control (CNC) systems

These technologies are integral to critical infrastructure such as manufacturing plants, power stations, and water treatment facilities, ensuring efficient and secure management of industrial processes.

4. Which regions are leading in OT market adoption?

As of 2023, North America dominated the OT market, accounting for approximately 37.7% of the global revenue. The United States is projected to lead the market by 2030, driven by advancements in technologies like the Industrial Internet of Things (IIoT), artificial intelligence (AI), and edge computing.

5. What are the key components driving the OT market?

Key components in the OT market include:

• Computer Numerical Control (CNC) systems: Leading the market with significant revenue, driven by demand across manufacturing, automotive, and aerospace industries.

• Building Management Systems (BMS): Projected to grow at the highest CAGR, fueled by the increasing demand for energy-efficient and sustainable buildings.

Order a free sample PDF of the Operational Technology Market Intelligence Study, published by Grand View Research.

#Operational Technology Market#Operational Technology Market Size#Operational Technology Market Share#Operational Technology Market Analysis

0 notes

Text

The Impact of Professional Transformer Installation on Electrical Safety and Reliability

Transformer installation in substations is a critical step in the development and maintenance of reliable power distribution systems. Whether for industrial facilities, utility substations, or commercial infrastructure, the proper handling, installation, and commissioning of transformers play a significant role in ensuring electrical safety, energy efficiency, and long-term equipment performance. This guide outlines the essential practices for safe and effective transformer installation while emphasizing the importance of working with experienced professionals to avoid operational failures and safety hazards.

Importance of Transformer Installation in Power Systems

Transformers are the heart of any electrical power system, enabling the efficient transmission and distribution of electrical energy across various voltage levels. Their role is essential in regulating voltage, reducing transmission losses, and maintaining the reliability of the grid. However, even a minor oversight in the installation process can result in severe consequences such as equipment failure, downtime, fire hazards, or even explosions. Therefore, ensuring precision during installation is not only about performance but also about ensuring safety and compliance with regulatory standards.

Pre-Installation Planning and Site Assessment

Safe and effective transformer installation begins long before the equipment arrives on site. Comprehensive planning and assessment of the substation location are essential. This includes evaluating the foundation to ensure it can support the weight and vibration of the transformer, planning for adequate ventilation and drainage, and ensuring that all grounding systems are properly designed. During this stage, engineers also confirm the compatibility of the transformer with other substation equipment and ensure that space is sufficient for operational and maintenance access.

Handling and Positioning of Transformers

Transformers are heavy and sensitive pieces of equipment that must be handled with extreme care during transportation and placement. Specialized lifting and rigging equipment are used to avoid physical damage. It is crucial to follow manufacturer guidelines and safety protocols while positioning the transformer on its foundation. Proper alignment ensures effective cooling and prevents mechanical stresses that can reduce the lifespan of the equipment. Ensuring the transformer is leveled correctly and anchored securely is a vital aspect of installation safety.

Electrical Connections and System Integration

Once the transformer is placed, the electrical connections must be made with precision. This involves connecting the high-voltage and low-voltage terminals, grounding the unit according to design specifications, and integrating protection and control systems. Improper connections can result in energy losses, overheating, or equipment failure. All terminals must be thoroughly inspected for cleanliness and secure fastening to prevent arcing or voltage imbalances. Integration with protection relays and SCADA systems must also be validated to ensure real-time monitoring and fault detection.

Testing and Commissioning Procedures

Before a transformer can be energized, it must undergo a rigorous series of tests to confirm its operational readiness. These tests include insulation resistance tests, transformer turns ratio (TTR) tests, power factor testing, and oil analysis if the unit is oil-filled. These procedures help identify potential issues that could lead to failures under load conditions. After testing, the commissioning phase includes energizing the transformer under controlled conditions and monitoring its performance parameters. Only after a successful commissioning process should the transformer be brought into full service.

Compliance with Safety Standards and Regulations

Transformer installation in substations must comply with national and international safety standards such as the IEC, IEEE, and BIS regulations. These standards ensure that the transformer installation meets minimum safety and performance benchmarks. Adhering to these guidelines is also crucial for insurance purposes and for passing regulatory inspections. Safety gear, lockout-tagout procedures, and fire prevention systems must be incorporated throughout the installation process to safeguard both personnel and equipment.

Choosing the Right Service Provider

A crucial factor that determines the success of a transformer installation project is the experience and expertise of the service provider. A professional team not only understands the technical complexities but also brings in valuable insights into site-specific challenges, regulatory compliance, and long-term maintenance requirements. For those seeking Transformer Installation and Commissioning Services in India it is vital to partner with companies that have a proven track record and deep industry knowledge. Manikaran Enterprises is one such company known for delivering high-quality transformer services across various sectors.

Maintenance and Long-Term Monitoring

Even after a successful installation, transformers require routine inspections and maintenance to ensure consistent performance and longevity. This includes thermal imaging, periodic oil testing, and mechanical checks to detect wear and tear. Remote monitoring systems can also provide real-time data on transformer health, enabling predictive maintenance and reducing the risk of unplanned outages. A proactive approach to maintenance not only reduces downtime but also extends the life of the transformer significantly.

Enhancing Reliability with Professional Support

The complexity and critical nature of transformer installation demand a strategic approach backed by technical precision, safety compliance, and expert supervision. From initial planning to final commissioning, every step must be executed with attention to detail. When handled correctly, transformer installation enhances the overall reliability and efficiency of the substation, minimizes risks, and supports the broader goals of a stable power supply. Engaging with professionals like Manikaran Enterprises, a Top Electrical Solution Company in Rajasthan ensures that your installation meets the highest standards of quality and safety.

Conclusion

Transformer installation in substations is a task that goes far beyond simply placing equipment on a site. It encompasses engineering design, safety compliance, skilled labor, and comprehensive testing. With the growing demand for uninterrupted power supply and the complexity of modern electrical systems, safe and effective transformer installation has never been more important. By following best practices and choosing the right partners, businesses can ensure operational success and safeguard their electrical infrastructure for years to come.

0 notes

Text

Powering the Production Line: Messung’s NX-ERA PLCs in Automotive Material Handling

In automotive manufacturing, precision isn’t a luxury, it’s a necessity. From chassis and engine assembly lines to the press shop and paint line, seamless material handling is critical to keeping production on track. Whether it’s coordinating conveyors, pick-and-place systems, or synchronizing with robotic cells, the need for intelligent control is constant.

Messung’s NX-ERA PLCs deliver this control with unmatched flexibility. With native support for Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link, they enable high-speed communication across robots, HMIs, VFDs, servo amplifiers, and central SCADA systems. Plus, with remote I/O modules and protocols like CANopen, our PLCs handle large-scale, distributed inputs and outputs effortlessly. Simply put, NX-ERA makes advanced, synchronized automation easy, even in the most demanding environments.

What is Material Handling in the Automotive Industry?

Material handling in the automotive industry involves the movement, positioning, storage, safety, and tracking of components and assemblies throughout the production process—from the arrival of raw materials to the final stages of vehicle assembly. Efficiency here is critical; any delay or misstep can disrupt the entire manufacturing flow.

Key areas such as the chassis and engine assembly lines, along with the press shop and paint line, rely heavily on sophisticated material handling systems, including conveyors, pick-and-place machines, and robotics, to keep production moving seamlessly. These systems must operate in perfect sync, often across large, distributed areas with thousands of I/O points.

The Brain Behind the Brawn: NX-ERA PLCs

Our state-of-the-art NX-ERA PLCs including the NX-ERA Xpress and NX-ERA Jet, are compact PLCs designed for high-speed, reliable control. These programmable logic control systems are the heart of any automated material handling system. By offering real-time control, seamless connectivity, and robust communication protocols like Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link. They interface effortlessly with robots, HMIs, VFDs, servo amplifiers, and centralized SCADA systems, ensuring reliability and scalability.

Here are some of its most impactful features:

High-Speed Processing Power

The core point of NX-ERA PLCs is that they are capable of real-time processing. These robot systems run as fast as your machinery, and the synchronization is important for the overall efficiency of the system. This compact PLC will guarantee flawless optimization for every aspect of the bottling line, be it controlling the work of conveyors or robotic manipulation.

Modular Design for Flexibility

The greatest feature of the NX-ERA PLC is its modular design. Production plants in the automotive industry often aim for some form of adaptability, and, thus, this feature is very helpful. It allows the installation to expand while the business is developing. The implementation of modularity means that the system can be integrated with any new equipment, production units, or additional features to ensure that there will be no disruption to the system performance.

Integrated I/O Modules for Streamlined Setup

Our smart and compact PLC integration contains integrated I/O modules that reduce installation and wiring times, thus also focusing on the fast-paced phenomenon in the automotive industry. For simplification of the things, input/output capabilities are now directly included in the integrated PLC system, which substantially reduces the external wiring as a result of which the setting up is speedier and less prone to mistakes.

Advanced Web Server Capabilities

It is safe to say that we are far off the days when engineers would have to be on site for them to physically track and diagnose issues on the factory floor. The capability of the built-in web pages of our NX-ERA PLC allows easy remote access for getting the actual real-time state of the diagnostics and monitoring. This feature is incredibly important in an industry that operates around the clock, as it allows maintenance teams to resolve issues remotely, reducing downtime and keeping things running smoothly.

The Role of the NX-ERA PLCs in Material Handling

In the automotive industry, material handling is integral to the success of the production process. From raw materials to semi-finished goods, and finally to finished products, materials need to be handled with precision. Automation is key to achieving this, and Messung’s NX-ERA PLCs are designed to make this process as efficient and effective as possible.

Here is how it is done:

Conveyor Systems Optimization

Conveyor systems, which carry parts between the workstations and at the same time keep the production continuously running, are the most popular form of material handling in the automotive plants. NX-ERA PLCs make sure that the system, no matter what, functions without any breaks by adjusting the speed of the conveyors to fit the pace of production. The real-time processing feature ensures that the system in question becomes flexible almost immediately, providing the assembly line without any interruptions and preventing the end line packing in the last round.

Predictive Maintenance to Maximize Uptime

The predictive maintenance of the system is seen as the golden nugget to maximize uptime. For the maintenance of a plant, having machines down during their run time is quite expensive. In the automotive industry, where the production rates run on a very tight schedule, even a moment's disruption would mean substantial losses. Our PLC Systems use a predictive maintenance system to keep a continuous check on the condition of the equipment. The control system will be equipped with predictive maintenance, which can track the system performance, increasing the change in predicting when maintenance is needed before failure occurs. These stains would reduce chances of equipment going down and also increase whole equipment machines productivity performance.

Power Management for Material Handling Equipment

How NX-ERA PLCs Integrate with SCADA Systems

Industrial automation relies not just on PLCs but also on supervisory control and data acquisition (SCADA) systems to monitor and control large-scale operations. The integration of NX-ERA PLCs with SCADA applications enhances material handling capabilities by providing plant operators with real-time insights into the performance of material handling equipment.

Real-Time Visualization and Data Monitoring

Data gathered from the cluster of service line sensors are then monitored by SCADA systems through real-time visualization and data troubling. By means of the material handling systems' connecting to the SCADA applications, operators are able to visualize every operation stage on a single interface. Our NX-ERA PLC assists the SCADA system in a way that allows real-time data visualization. As for plant automation, this integration enables the operators to redesign the production line and fabricate the survey that they are in full command, including the conveyor speed, robotic movement, and electrical power consumption.

Alarming and Fault Diagnostics

Unexpected malfunctions are a part of any complex system, but SCADA and PLC integration ensures they are dealt with swiftly. The NX-ERA PLC can send alerts to SCADA systems when material handling equipment encounters an issue, whether it’s a malfunction in a conveyor belt, a sensor failure in a robotic arm, or an electrical fault. This proactive approach helps resolve issues before they lead to extended downtime.

Historical data analysis for continuous improvement

Other benefits of integrating the SCADA system with the NX-ERA PLC is to have an ability to analyse historical data. These past data performances can better help the plant managers to see trends, adjust production schedules, and improve the efficiency of the material-handling systems over the long period. In actuality, the PLC saves and disposes of necessary data. This information, then, is fed into the SCADA system and used for analysis and presentation purposes.

The Future of Material Handling with NX-ERA PLCs

As the automotive industry embraces Industry 4.0, NX-ERA PLCs are positioned at the forefront of the shift towards smarter, more connected manufacturing systems. This is brought about by switching to smarter, more connected production systems. Thanks to NX-ERA PLCs, which are able to integrate with SCADA applications, robots, and power supplies, you can now easily build a factory that can quickly adapt to changes in the current demand and the production process.

Benefits Include:

More automation and efficiency with the increasing factories

As factories become more automated, the role of PLCs like the NX-ERA will only grow. The future of material handling will rely on even more precise and automated systems, from fully autonomous robots to smart conveyors that adjust their speed and behavior based on real-time conditions. The NX-ERA PLC is ready to support this evolution with its high-speed processing and robust integration capabilities.

Energy Management and Sustainability

Green manufacturing is a critical concern for the industry today. Automotive manufacturers demand advanced NX-ERA PLCs in a bid to bring down the environmental impact of the production. An essential element that plays a pivotal role in power solutions, predictive maintenance, and derived data for operational efficiency is a way for these to reduce the consumption of energy.

Real-Time Data and IoT Connectivity

With the rise of the Internet of Things (IoT) in manufacturing, NX-ERA PLCs will continue to integrate with a broader network of connected devices. This real-time data flow will empower automotive plants to make more informed decisions and improve their material handling systems.

Conclusion: The Future of Material Handling in the Automotive Industry

In the race for efficiency and innovation, Messung’s NX-ERA PLCs are the pit crew that keeps material handling equipment running at peak performance. Their combination of advanced features, modular design, and seamless integration with SCADA systems positions them as the ideal solution for automotive manufacturers aiming to stay ahead of the competition.

As automotive plants move towards smarter, more automated manufacturing processes, the need for reliable, high-performing PLCs like the NX-ERA will only continue to grow. By embracing the capabilities of Messung’s NX-ERA PLCs, automotive manufacturers can ensure that their material handling systems operate efficiently, sustainably, and with minimal downtime, ultimately contributing to the ongoing success of the industry.

In this fast-paced industry where precision is the name of the game, Messung’s NX-ERA PLCs are the game changers that automotive manufacturers need to optimize their material handling systems and maintain a competitive edge in the global market.

#chassis and engine assembly lines#Modbus TCP/IP#Ethernet/IP#EtherCAT#OPC-UA#remote I/O modules#CANopen#compact PLCs#programmable logic control systems#SCADA systems#automotive industry#PLC system#material handling#PLC Systems#material handling systems#SCADA applications#PLC integration#Automotive manufacturers#Internet of Things (IoT)

0 notes

Text

System Integrator Market Size, Share, Trends, Industry Growth and Competitive Outlook

Global System Integrator Market - Size, Share, Demand, Industry Trends and Opportunities

Global System Integrator Market, By Service (Infrastructure Integration, Application Integration, Consulting), Technology (Supervisory Control and Data Acquisition (SCADA), Programmable Logic Controller (PLC), Programmable Automation Controller (PAC), Remote Terminal Unit (RTU), Distributed Control System (DCS), Manufacturing Execution System (MES) and Manufacturing Operations Management (MOM), Product Lifecycle Management (PLM), Human-Machine Interface (HMI), Advanced Process Control (APC), Operator Training Simulator (OTS), Safety Automation), End User (IT and Telecom, BFSI, Healthcare, Retail, Manufacturing, Energy and Utility) - Industry Trends.

Access Full 350 Pages PDF Report @

**Segments**

- **By Service:** The system integrator market can be segmented based on the services offered, such as consulting, design and development, maintenance and support, and integration & implementation services. Organizations often require system integrators to provide expertise in these areas to ensure the successful integration of technologies into their existing infrastructure.

- **By End-User:** Another key segmentation factor for the system integrator market is based on the end-user industries served. Various industries like IT & telecom, BFSI, healthcare, manufacturing, retail, and others have distinct technology requirements, which necessitate the need for specialized system integrators catering to their specific needs.

- **By Region:** Geographical segmentation plays a crucial role in the system integrator market as technology adoption and requirements vary across regions. Different regions like North America, Europe, Asia Pacific, Latin America, and Middle East & Africa have unique market dynamics that influence the demand for system integration services.

**Market Players**

- **Accenture:** One of the prominent players in the system integrator market, Accenture offers a wide range of consulting, technology, and outsourcing services to help organizations integrate and optimize their IT infrastructure.

- **IBM:** IBM is another key market player providing system integration services to address the complex technology needs of businesses across various industries.

- **Deloitte:** Deloitte's system integration services focus on helping organizations streamline their operations and enhance efficiency through the seamless integration of technologies.

- **Capgemini:** Capgemini is a global leader in consulting, technology services, and digital transformation, providing advanced system integration solutions to enable businesses to achieve their strategic objectives.

- **TCS (Tata Consultancy Services):** TCS is a leading IT services, consulting, and business solutions organization that offers comprehensive system integration services to drive innovation and maximize operational performance for its clients.

The system integrator market is witnessing significant growth due to the increasing digitization of businesses across industries. As organizations strive to enhance their operational efficiency and leverage advancedThe system integrator market is experiencing robust growth as businesses across industries continue to digitize their operations to improve efficiency and stay competitive in the modern business landscape. With the increasing complexity of technology ecosystems and the need for seamless integration of various platforms and solutions, the demand for system integrators is on the rise. These market players play a crucial role in helping organizations navigate the challenges associated with integrating new technologies into their existing infrastructure.

Segmentation of the system integrator market based on services offered provides insights into the diverse needs of organizations seeking integration solutions. Consulting services are essential for understanding the specific requirements and goals of the business, while design and development services focus on creating tailored solutions to meet these objectives. Maintenance and support services are crucial for ensuring the smooth functioning of integrated systems, while integration and implementation services play a key role in executing the integration process effectively. By catering to these different service requirements, system integrators can address the unique needs of their clients and deliver value-added solutions.

The segmentation of the system integrator market by end-user industries reflects the diverse technology requirements across different sectors. Industries such as IT & telecom, BFSI, healthcare, manufacturing, and retail have specific technological needs that require specialized expertise for successful integration. System integrators with industry-specific knowledge and experience can provide tailored solutions that address the unique challenges faced by organizations in these sectors. By understanding the distinct requirements of various industries, system integrators can develop customized integration strategies that drive business growth and innovation.

Geographical segmentation also plays a significant role in the system integrator market, as technology adoption and market dynamics vary across regions. North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa each present unique opportunities and challenges for system integrators. Local regulations, infrastructure, and business practices all influence the demand for integration services in these regions. By understanding the specific needs of each market, system integrators can tailor their services to meet the requirements of local businesses and drive growth in the respective regions.

Prominent market players such**Segments**

- **By Service:** The system integrator market is segmented based on the services offered, including consulting, design and development, maintenance and support, and integration & implementation services. Organizations rely on system integrators to provide expertise in these areas to ensure successful technology integration.

- **By End-User:** The system integrator market is segmented based on the end-user industries served, such as IT & telecom, BFSI, healthcare, manufacturing, and retail. Different industries have specific technology requirements, leading to the need for specialized system integrators catering to their unique needs.

- **By Region:** Geographical segmentation is crucial in the system integrator market as technology adoption varies across regions. North America, Europe, Asia Pacific, Latin America, and Middle East & Africa each have distinct market dynamics influencing the demand for system integration services.

**Market Players**

- **Accenture:** Offering consulting, technology, and outsourcing services, Accenture aids organizations in integrating and optimizing their IT infrastructure.

- **IBM:** IBM provides system integration services to address complex technology needs across various industries.

- **Deloitte:** Deloitte focuses on helping organizations streamline operations and enhance efficiency through seamless technology integration.

- **Capgemini:** As a global leader in consulting and digital transformation, Capgemini delivers advanced system integration solutions for businesses to achieve strategic objectives.

- **TCS (Tata Consultancy Services):** TCS, a leading IT services organization, offers comprehensive system integration services to drive innovation and

Core Objective of System Integrator Market:

Every firm in the System Integrator Market has objectives but this market research report focus on the crucial objectives, so you can analysis about competition, future market, new products, and informative data that can raise your sales volume exponentially.

Size of the System Integrator Market and growth rate factors.

Important changes in the future System Integrator Market.

Top worldwide competitors of the Market.

Scope and product outlook of System Integrator Market.

Developing regions with potential growth in the future.

Tough Challenges and risk faced in Market.

Global System Integrator top manufacturers profile and sales statistics.

Key takeaways from the System Integrator Market report:

Detailed considerate of System Integrator Market-particular drivers, Trends, constraints, Restraints, Opportunities and major micro markets.

Comprehensive valuation of all prospects and threat in the

In depth study of industry strategies for growth of the System Integrator Market-leading players.

System Integrator Market latest innovations and major procedures.

Favorable dip inside Vigorous high-tech and market latest trends remarkable the Market.

Conclusive study about the growth conspiracy of System Integrator Market for forthcoming years.

Frequently Asked Questions

What is the Future Market Value for System Integrator Market?

What is the Growth Rate of the System Integrator Market?

What are the Major Companies Operating in the System Integrator Market?

Which Countries Data is covered in the System Integrator Market?

What are the Main Data Pointers Covered in System Integrator Market Report?

Browse Trending Reports:

Video Conferencing Systems Market Wireless Gigabit Market Functional Mushroom Powder Market Water Based Lamination Adhesive Market Wash Basins Market X-ray Digital Imaging Systems Market Water Tight Doors Market Data Center Rack Power Distribution Unit (PDU) Market Point-of-Care Testing (POCT) Market Melamine Formaldehyde Market Naphthalene Derivatives Market Shape Memory Alloy Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]

0 notes